One of the objects on Thingiverse that I have wanted to try for quite a while is the Maker Faire Print in Place Robot.

This is a fairly tortuous print and really separates out the top end printers, if your printer is not accurately calibrated, then you can have issues with sections fusing together that should be able to move, likewise, if your bridging is not great, again this will cause parts to fuse.

My first attempt only made it about 6 layers before it started catching on peeling sections and on the 7th layer dragged so badly that it offset the print head by 7mm in the Y direction.

I was not watching the print at the time, but heard it drag and knew that the print was ruined.

The second attempt failed at about the same place, despite my trying to push the peeling ends back down again.

This despite the use of Kapton tape on the glass, that had been cleaned with Acetone and using the heated bed set at 60C.

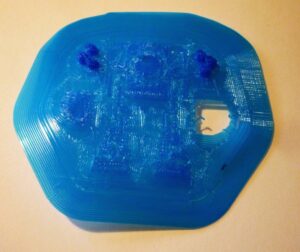

I then decided to try printing with a raft in order to keep the small parts attached to the print bed.

This was going fine until about layer 12 or 14 when the print head skipped about a filament’s width in the X direction and when I decided to disconnect the heated bed managed to short the MOSFET against a couple of the exposed pins on the SD card reader which halted the print.

All the electronics were still fine and after a quick reset we were back in business again.

The print removed fairly readily from the raft and definitely looked like it had promise.

For the next attempt I decided since I was using such a wide raft that I would forgo the use of the heated bed.

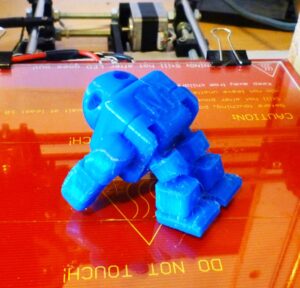

This print was allowed to continue until completion which took some 4 hours or more, I could no doubt have printed it faster if I had used a lower infill setting than the 40% honeycomb that I normally use, maybe next time.

Here is the finished article seconds after it finished printing, a little stringy but otherwise looks OK.

In this picture it almost looks like the robot is melting onto the print surface.

I allowed it to cool for a while before removing it from the print surface.

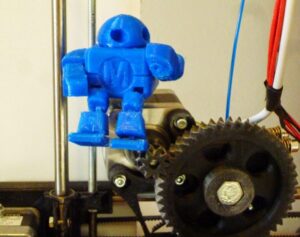

The raft removed fairly easily, the supports behind the shoulders required a fair bit more effort.

All of the joints, including the head, whist initially fused in place all released with minimal force and articulate as they should, with the exception of the right foot which snapped at the ankle when I tried to lever it down.

The 60 degree overhangs on the underside of the arms are not perfect, but there are no drooping loops either.

In all a successful exercise, although proving that my printer still has room for improvements.

i like this post, we visit again for more updates , thanks for sharing this article.

cheap artificial grass

i like this post, we visit again for more updates , thanks for sharing this article.

cheap artificial grass