When I assembled the various moving parts of the Ord Bot Hadron frame, they were all very tight

even with the eccentric nuts at their widest settings.

Because they are so tight, the wheels develop flat spots that then makes it very difficult to move the various axes, they also manage a complete revolution of the wheel and then ‘clunk’ into the flat spot again.

So I decided to measure a spare wheel and that is when I realised why they were binding.

The outer dimension was 25.50mm, the bottom of the V in the wheel was 20.50 and when I checked the angle of the V that was not 90 degrees either, but somewhere around 80 degrees.

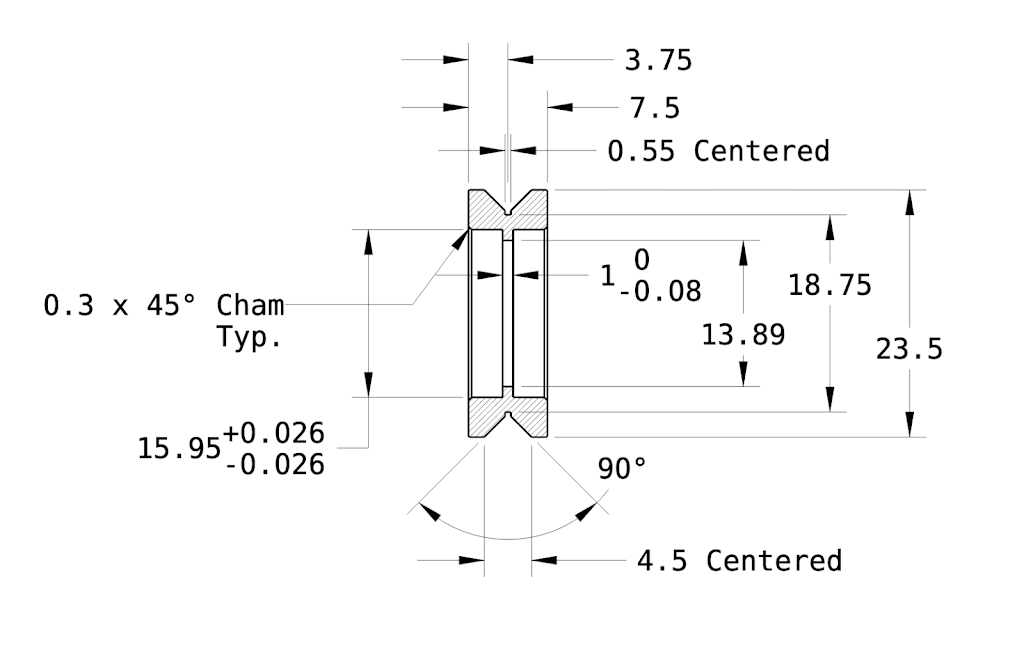

The official V wheels as designed by Bart Dring,

have an outer dimension of 23.5mm and the bottom of the V is 18.75mm.

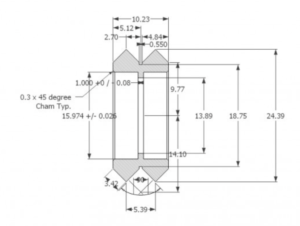

Even the OpenBuilds V wheel designed by Mark Carew,

that my wheels are supposedly clones of have an outer dimension of 24.39 and bottom of the V again should be 18.75mm.

Well I suppose that is what you get for buying cheap from China instead of the genuine item from Inventables or OpenBuilds.

The next problem was to work out how to modify them so that they can actually be adjusted.

I first tried using a large penny washer either side of the V wheel and tightening together with an M5 screw and nut, but this was nowhere near tight enough and any kind of pressure on the wheel caused it to rotate inside the washers.

I then noticed that the bearings were 11mm in diameter which is practically the same size as an M8 washer, so if I push out the bearings and add 3 x M8 washers each side and tighten onto an M8 screw, I have a mandrel for turning the wheels.

Mandrel parts dismantled

I could now turn the wheels in the lathe.

The first few, I machined down to the supposed correct inner dimension of 18.75, but when assembled on the 3D printer, these were too loose.

I then decided to just machine the groove to 90 degrees by taking the minimum amount off possible to touch the bottom of the groove with the tool.

V wheel before machining

and after

After machining all of the V wheels, the axes now move smoothly and have some adjustability using the eccentric nuts.