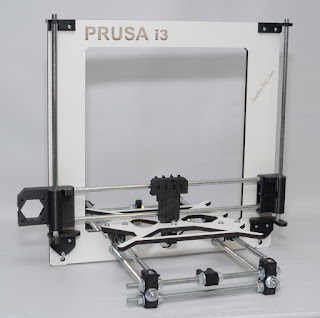

Well I am still not happy with my Prusa frame, but I have not completely given up on it yet.

I have glued the Nylon Screw Insulators into the various holders and glued these into the X axis ends, these slide reasonably well along the smooth rods, but will probably be better with a little silicone spray or light grease.

I have also bought a set of printed Prusa i3 parts for £25.00 + £4.00 P&P on Ebay which I did not think to be a bad price, no extruder, but I am not bothered about that and if anything am happy to be spared the cost.

One of the things I like about this printer, and some of the other recent printers (Mendel 90, Quantum Ord Bot, Printrbot, etc), is that the Z axis steppers are at the bottom, adding weight and stability where it is required, rather than at the top where they are simply adding to the instability of the frame, with potentially pendulous mass and vibrations high up on the frame.

Another thing I like about this printer is the relatively small number of printed parts and all of the other parts are low cost and easily obtained, I believe this will actually be a fair bit cheaper to build than a Prusa i1 or i2.

I believe the parts are those shown as the JoFinal set on GitHub and can be seen here used with this laser cut SeeMeCNC frame:

The frame and bed is not a bad price at $32.00, however shipping to the UK would be more than the cost of the frame, making it a bit expensive, now if someone were to offer these at around £20.00, then I am sure they would sell well.

The metal version of the frame can be seen here, however this is never going to be cheap when a 500x500x6mm sheet is around £40.00 including shipping before any cutting.

The printed parts require a little work as they do not all fit the bearings, rods, etc quite right, and the captive M5 nut has no hope of fitting in the X motor end and idler, so some work required there as well, but I am generally pleased with the parts, on the plus side the holes for the motors all line up well.

As a result of this and also wanting to make use of some T2 belts from various printers I have scrapped, they just happen to be the compatible with the drive gears that came with my stepper motors, so no additional cost, but I need to adjust the sizes of the bars and boards in order to make use of them. So I modelled all the parts in Sketchup and adjusted the bar lengths and axis locations until the belts I had would work.

The print area is 215x215x250mm despite the footprint of the printer being smaller than the official dimensions, I don’t really see the point in making the axes any longer/wider, it just means longer belts and rods for no real gain in print area unless you want to print serious overhangs beyond the “standard” heated bed, or make a much larger heated bed yourself.

The Bowden extruder is a variation on the Eventorbot extruder.

Here is my version, it is intended to be made from a single block of aluminium, but could just as easily be printed, again the drive gear came for free with the stepper:

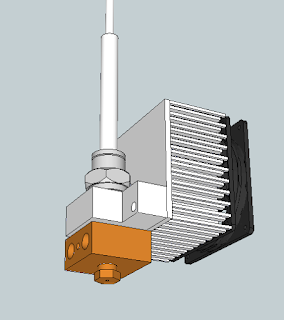

The Hot end is a variation on the Huxley Hot End

Here is my version, which uses 3mm filament instead of 1.75mm, mainly because I already have suitable pneumatic fittings for this size of tubing:

The nozzle is from a set of LPG gas jets, the heatsink and fan are items that I have from my collection of old PC hardware (remember never throw anything potentially useful away :o)

I ordered 10 x LM8UU bearings for £3.24 and free shipping from a Hong Kong seller on Ebay, these arrived quite quickly, although unfortunately the package was damaged in the post and 2 of the 10 bearings fell out and were not received. The package when it arrived was enclosed in a plastic bag from the Royal Mail apologising for the state of the package – I am taking the matter up with the Royal Mail and the vendor.

I also ordered 10 x 624ZZ bearings (4x13x5mm) for £4.80 + £0.90 P&P, as these are used instead of 608ZZ bearings (8x22x7) with these printed parts, some 5mm studding at £0.46 a meter, and additional nuts, washers, etc, from Orbital Fastners (I needed to buy some other stuff from them anyway so now was a good time to place the order, especially as it is free next day delivery on orders over £20.00).

The board I intend to use is melamine coated MDF from Homebase at £7.99 for a sheet 1200x220x15mm. If I cut this down the middle and then into the lengths I require, it should be perfect, and just one or 2 cut edges to worry about sealing. I can also use it full width for the Y bed.

i like this post, we visit again for more updates , thanks for sharing this article.

cheap artificial grass

This comment has been removed by a blog administrator.

This comment has been removed by a blog administrator.

The article is much informative which i was searching for .Nice intro good explanation thanks for sharing.

Enrgtech Electronic Components