I am as interested as the next guy in saving money. I also want to make my own things.

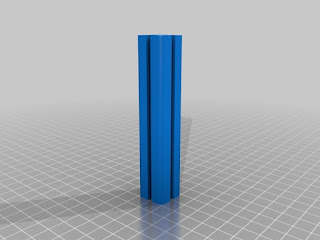

One of the items I have been interested in making is the 20mm T-Slot from Thingiverse shown below:

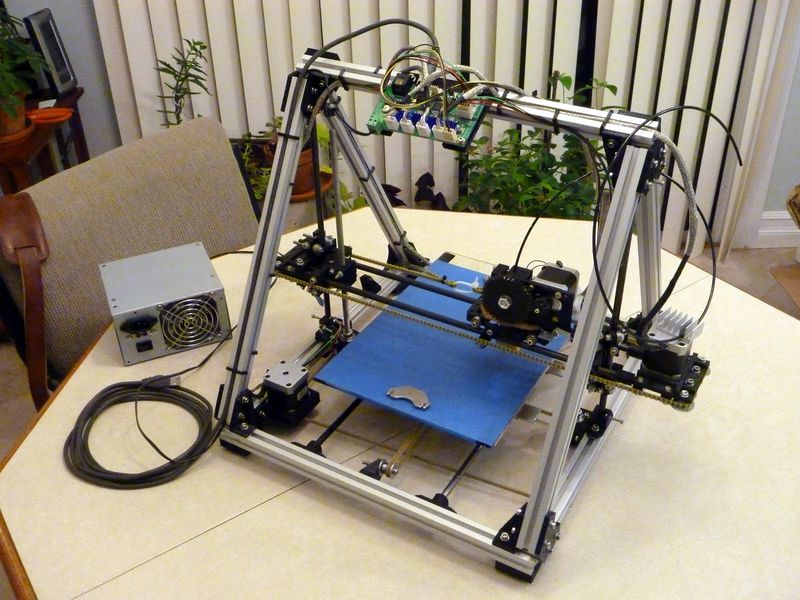

Say for sake of argument I was wanting to build a Prism:

This uses 9 x 400mm lengths of 20mm aluminium profile extrusion.

Now the volume of a 400mm section of the Plastic T-Slot with 100% solid fill is about 90cc.

The cheapest price I can find for ABS at the moment is Buy 3D Ink, where it is $39.95 for 3lb of 3mm filament (without shipping to the UK), this equates to about £18.30 per Kg, or £0.0183/g (there may well be cheaper product out there, but bear with me for now).

An average price for PLA is about £0.21 a metre from Faberdashery, where it is £21.00 for a 100m coil, about 880g (again without shipping) or £0.0238/g.

ABS is about 1.04g/cc

PLA is about 1.379g/cc

So to make the item would require 93.6g of ABS filament (1.04*90) or 124.1g of PLA filament (1.379*90).

So our manufacturing costs for each item would be £1.71 for ABS (93.6*£0.0183) or £2.96 for PLA (124.1*£0.0238), so looking at total costs of £15.39 for ABS (9*£1.71) or £26.64 for PLA (9*£2.96) for the 9 lengths of 400mm T-Slot.

Ignore for the moment potential difficulties involved with joining several 100m pieces together to make a 400mm length, acetone apparently works quite well as a glue for ABS, other items are more suitable for PLA.

Now consider the cost of buying the actual aluminium extrusion instead from KJN, at £2.90/m (with a free cutting service), which equates to £1.16 per 400mm length and £10.44 for all 9 pieces (again shipping has been ignored).

Here is a classic example where the industry standard, off the shelf item is substantially cheaper than attempting to manufacture the part yourself.

I am all for innovation and making as many parts for yourself as possible, but really fail to see the point when it works out 47-155% more expensive than buying an off the shelf product.

Now making the motor mounts, weird shaped brackets, one off items, etc, is where these machines come into their own – very low setup costs for small production runs (one or just a couple) for bespoke items that you would be hard pressed to locate in any shop and would cost a small fortune to have someone manufacture for you.

Just remember, that just because you have a 3D printer and you potentially can make just about anything you set your mind to, doesn’t mean it will be cheaper than ordering it from someone who sells huge quantities of an equivalent product and can leverage economies of scale.

The article is much informative which i was searching for .Nice intro good explanation thanks for sharing.

Enrgtech Electronic Components