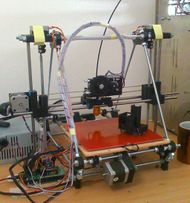

This blog will be following the development of my Reprap Prusa Mendel, from parts source contemplations, through the build process and on to things I eventually get around to printing and all the highs and lows in between.

The main issue for all people joining this 3D printer revolution is how to build your first machine, building the second one, or first child, is relatively straight forward – you just use your existing printer, but when you don’t already have a printer you have a couple of options:

- Build some sort of bootstrap (repstrap) machine, extruder attached to a CNC machine of some sort to print out the parts for your printer.

- Buy a full or partial kit of parts that someone else has put together

Now whilst I am all for supporting the reprap community, I am also a cheapskate and object to paying some of the prices being charged for these kits, I am perfectly happy sourcing the vitamins, motors, electronics, etc from the cheapest suppliers I can find, rather than paying the premium for someone else putting it all together in a kit.

I have been researching parts suppliers, electronics options, etc. for quite a few months now and have made a few decisions and actually splashed out and bought a few items.

To that end I have decided to go with a cast set of parts including a Wades Extruder from Metrix Create:Space at $50.00 and $15.00 shipping to the UK (£42.20), these parts may not last forever, and will need drilling, but I am sure they will last long enough for me to print at least one child’s worth of parts, probably many more, but they are a whole lot cheaper than the going rate of about £80.00 for an equivalent set of printed parts.

I have decided to go with the Sanguinololu approach for the electronics, mainly because I feel it is a neat and compact solution. I like the RAMPS idea for Arduino, but believe the Sanguinololu can be built for less, has a smaller footprint and looks neater. I also really like the Repic approach and will probably try this for my next controller – all through hole construction, PCB can be milled on the printer, PIC can be obtained for free (if you request a sample), but is still in development and is quite a steer from the ATMEGA based controllers that are currently the norm.

Rather than buy a ready built one, complete with drivers for £99.00, I have bought a 1.3a circuit board from Ebay for £4.50, and a couple of FTDI chips again from Ebay for £2.54 each, with free or minimal postage costs. I am thinking about some StepStick drivers from Ebay at £8.29 each. The remainder of the electronic components will be coming from Rapid or from various multi packs of resistors and capacitors I have previously bought from HK – total cost should be around £50-60.00 and doing my own soldering. I’ll add it all up properly when I have all the parts, along with the total cost of this build, just to see what it actually cost me.

The stepper motors I have bought, in keeping with my cheapskate nature, are used rather than new items, again from Ebay, under £30.00 for 5 Nema 17 steppers, I actually bought a set of 5×29 oz/in steppers and a set of 4×55 oz/in steppers as I need one with with the higher torque for the extruder. I will use the others, either on a second Prusa, or on a heated wire foam cutting CNC machine.