The TCT show was held at the NEC in Birmingham over 30th September and 1st October 2015, I attended on the last of the two days, arriving at about midday and expecting to be on my way home by about 14:00 – how wrong I was!

I new in advance that most of the exhibitors were going to be big business looking to sell their products or services, but was surprised at how many smaller firms, individuals and other new start-up people were there, along with elements of the reprap community.

I was also surprised at how many of the larger company representatives were more than happy to talk to someone who was highly unlikely to be in the market for one of their machines.

As expected Stratasys had one of the largest displays and many of the other print bureaus were also using their machines to promote their own business.

Autodesk were promoting their Ember resin based 3D printer – a snip at $5995.00 (£3870.00).

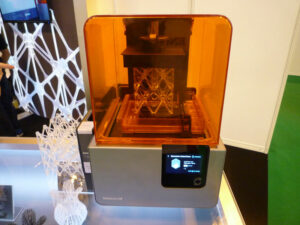

This is most likely competing with the likes of Formlabs and their new Form 2 printer which currently retails for €3299.00 (£3000.00).

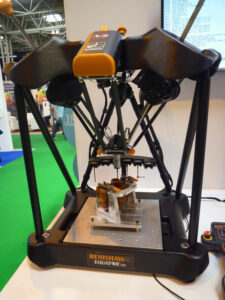

Another highly impressive piece of equipment on display was Renishaw’s Equator, their high speed delta comparative gauge for parts inspection.

I am always interested in what Renishaw are doing as my brother-in-law works for them, and I went to school with the son of the owner of the company.

I had a long discussion with the guys from ReprapWorld about the sliders I am using on my Kossel Mini printer, this is an area that they would like to explore further for use on one of their larger designs.

I would like to thank them once again for the spools of copper and bronze PLA they gave me at the end of the show as part of their raffle.

Another area that caught my eye was the kideville product from the start-up company kidesign, this is a collaborative city design project for schools, that incorporates design, CAD, 3D printing and teamwork, each student has a design spec for one element of the city that is eventually printed and then included in the city on the grid board.

Towards the end of the show I spotted the Roland iModela, which for £499.00 ($750.00) can mill, engrave and 3D print in it’s 86x25x26mm build envelope and pretty much every part is available as a spare in their parts store.

I would also like to thank Sam Deng of 3D Elements for kindly providing me with a half a dozen 50g (about 12m) samples of their PLA filament to try out after some very interesting discussions regarding their various filaments, some of which reacted to light and others to temperature.