I finally decided to start making all of the gears that were missing from my lathe change gear set.

The full set is supposed to be something like:

20, 25, 30, 35, 38, 40, 40, 45, 50, 55, 60, 65, 70, 75, 80, 85, 90, 95, 100, 105, 127.

However I am going to make an extra 20 tooth and throw in a 63 tooth as well, as it may still take me a while to actually make the 127 tooth gear.

With the 63 tooth gear I can cut most of the metric pitches with a percentage errors of 0.012-0.013% which translates to 0.001-0.013mm error in 10 pitches, depending on the thread, all of which are too small to be forth worrying about and probably within the manufacturing tolerance of a factory thread anyway.

I purchased a sheet of 10mm dural from eBay , that was approximately 610x270mm, back in 2016 for £10.00 with £6.30 P&P with the intention of using it for cutting out my missing gears, I decided now was as good a time as any to actually start this process.

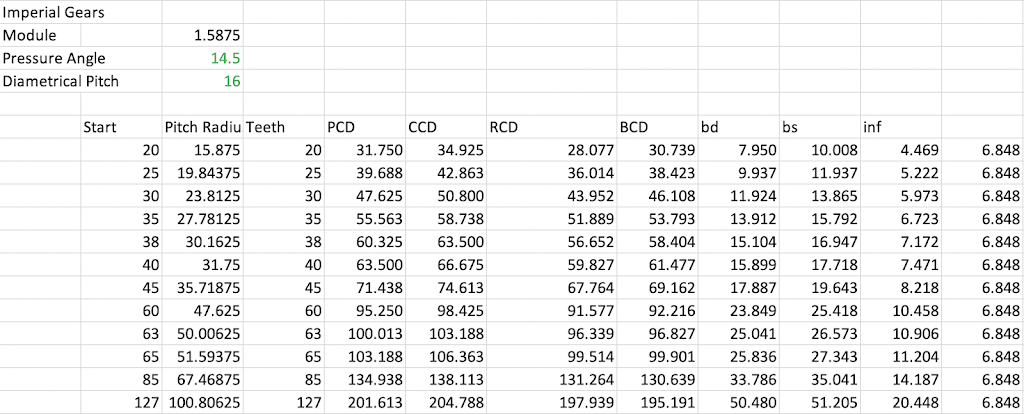

First off I worked out the dimensions for all of my missing gears.

Next I located round items in my garage that were of about the same diameter as each of the gears such that I could draw around them on the sheet of dural.

I then proceeded to cut them out on my bandsaw and cut them closer to the marked lines to reduce the amount of machining that would be required.

I eyeballed the centre of each blank and then drilled a 19mm hole in the middle using my mini mill, stepping up from 8mm, through 12mm, 16mm and finally 19mm as my pillar drill’s slowest speed was way too fast for drilling the 19mm hole without insane levels of chatter.

I then mounted the blank on the mandrel I made for the 40 tooth gear some time back and turning the blank round to the RCD diameter shown in the spreadsheet.

I have yet to drill the 85 and 127mm blanks as they are both too large to fit in the vice on my mini mill.

The 127 tooth gear, at 205mm finished diameter, is way too big to turn on my lathe as it does not have a gap bed and only has 3.5″ (88.9mm) centre height, which means a maximum diameter of 7″ or 177.8mm can be turned.