Back in July of 2014 I bought a Boxford morse taper 2 chuck adapter.

The first step was to machine off the existing threads and the register down to 1 1/4″.

In order to cut the threads, I inserted a 3MT to 2MT adapter in the spindle nose and then inserted the chuck adapter and supported the nose with a rotating centre, this also helped prevent the adapter from slipping as it does not have a full length taper.

Next I needed a gear train suitable for threading at 9TPI, which on my lathe is a 40 tooth drive gear, a 90 tooth final gear and anything as an intermediary, I chose to use a second 40 tooth gear.

I used a 55 degree carbide insert threading tool and ran the lathe forwards and backwards in back gear at the slowest speed to give me a chance of stopping the tool before it hit the collar.

When I believed I was close to the final size I moved the tailstock centre and tested the thread with a face plate.

Here is the chuck adapter at final size with the face plate mounted.

The shoulder of the chuck adapter is a close as this lathe gets to an actual register.

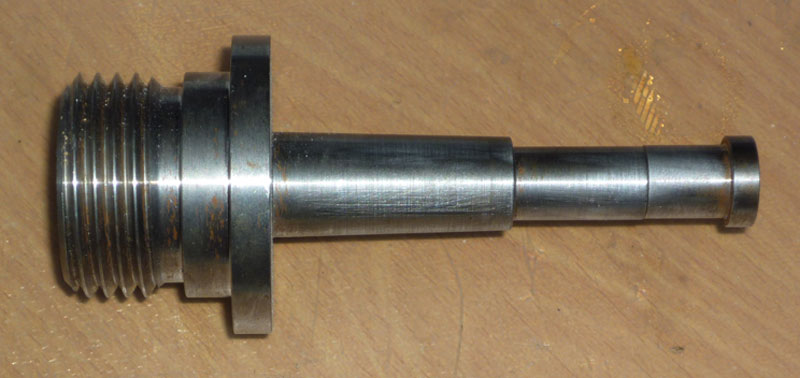

The finished item.

I need to see where I have put the piece that attaches to the rear of the chuck adapter for securing it in a rotary table.