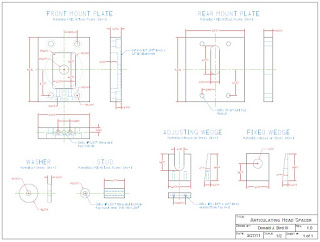

The articulating spacer for the SX2 is a design by Donald Bird that was posted on CNC Forums.

The plans are all imperial, but this is a metric sized mill, so I converted all of the dimensions to metric and drew it up in Fusion 360.

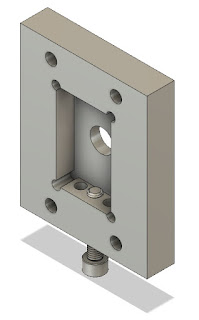

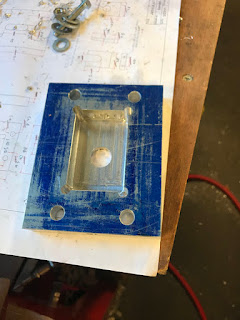

This first piece is the front mount plate that is 110x88x19mm.

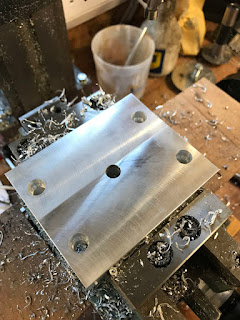

I started off by squaring up a suitable piece of aluminium.

It was somewhat rough on the rear side, so I decided to flycut it flat.

Next I drilled the mounting holes 8.7mm, then counter bored 14mm to a depth of 9mm.

The centre hole is about 10mm at this point.

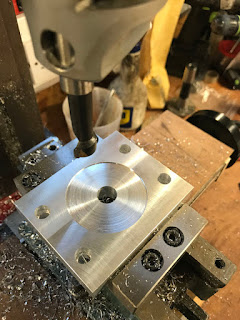

The centre hole was enlarged to 16mm and then counter bored at 63.5mm to a depth of 0.5mm.

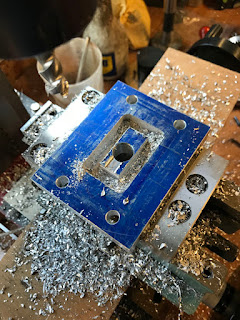

The part was then flipped over and I started cutting the offset pocket with a 3 flute 10mm carbide endmill.

This shot was taken after clearing the initial pile fo swarf.

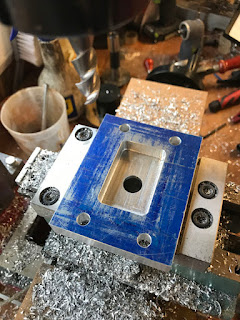

Next up milling off the central chunk to complete the pocket.

followed by a cleanup pass to the final dimensions.

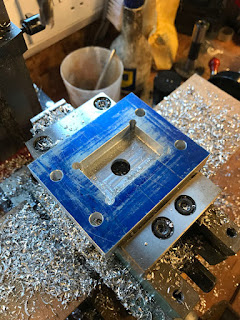

Clearance chamfers were then cut with a 6mm carbide endmill and the corners squared off.

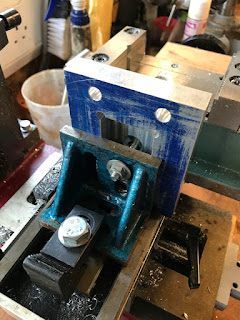

The part was then clamped to the table to allow enoughh height for drilling vertically.

The central hole was drilled through and tapped M8, the outer holes were drilled through 6.5mm and counterbored 10mm to a depth of 9.5mm.

The finished piece, just needs the blue marker cleaning off.

Those with keen eyes may notice the hole at the bottom where I started drilling the M8 hole on the wrong end!