I finally decided to start making the mechanical parts for my CNC conversion.

This is a drawing showing various stages of axis mount evolution in exploded form.

The ones nearest the middle are the ones that I am actually going to build, starting with the stepper mounts.

I have decided to go with 60mm square tube with a 4mm wall instead of 4 pillars or 2 plates for the additional rigidity it will offer.

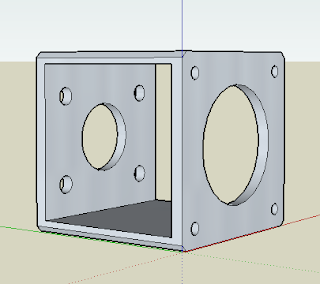

This is the model of the mount itself

I may or may not actually add the chamfer to the edges, I will play that element by ear for now.

The tube was purchased from ebay seller forwardmetals at £19.07 ($28.60) + £8.49 ($12.74) shipping for a 1m length, so about £1.65 ($2.48) per stepper mount. I intend to make a few other CNC machines at some point, and will use this tubing for those mounts as well.

I cut three lengths of the square tube at just over 60mm in length, milled the cut edges square and reduced the length to exactly 60mm

Next I bored out a centrally located hole to 40mm to clear the raised section on the front of the stepper motor.

Drilled 4 holes on a 33.3mm PCD

Then bored a matching hole on the rear at 24mm diameter and then 4 holes at 40mm apart horizontally and 30mm apart vertically.

Then repeated for the other 2 mounts.

Views of the different faces of the mounts

Here is one attached to a stepper motor to check the fit.