Following on from my previous post, I decided to have a go at making a new lead screw nut for my Mellor lathe.

I purchased a piece 300mm length of 36mm round Acetal bar from ebay seller diamondengineeringsupplies for £5.99 along with a few other pieces of Acetal that I intend to use for some other projects.

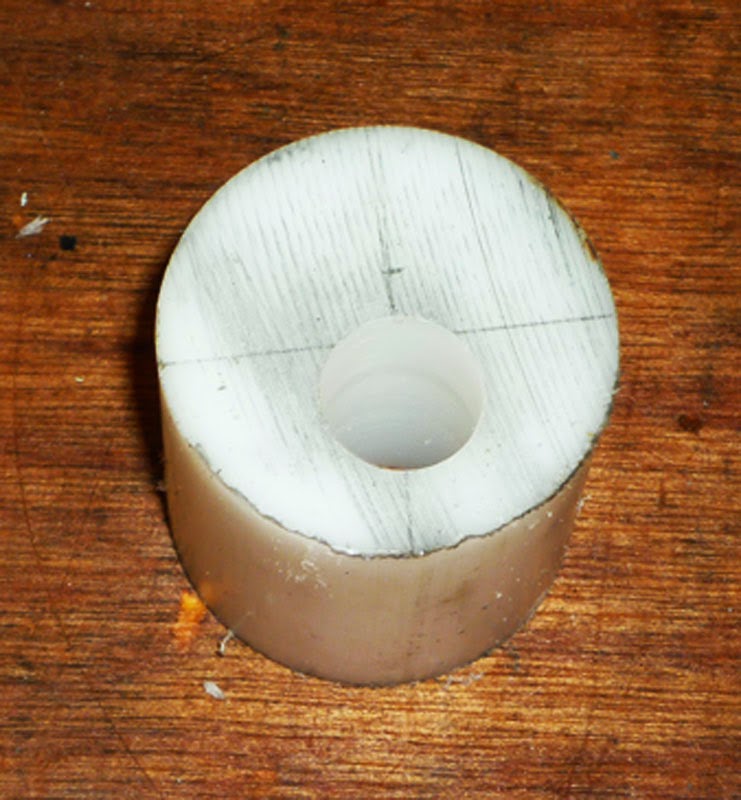

I cut off a 35mm length and then started drilling the offset hole for the new thread, the desired hole size is the outer diameter of the thread, less the height of one thread, which came out to 13.5mm

I started with a 6mm, then 10mm and finally a 13mm drill and decided that this was probably close enough.

Next I cut along the centre line of the new hole with a slitting saw.

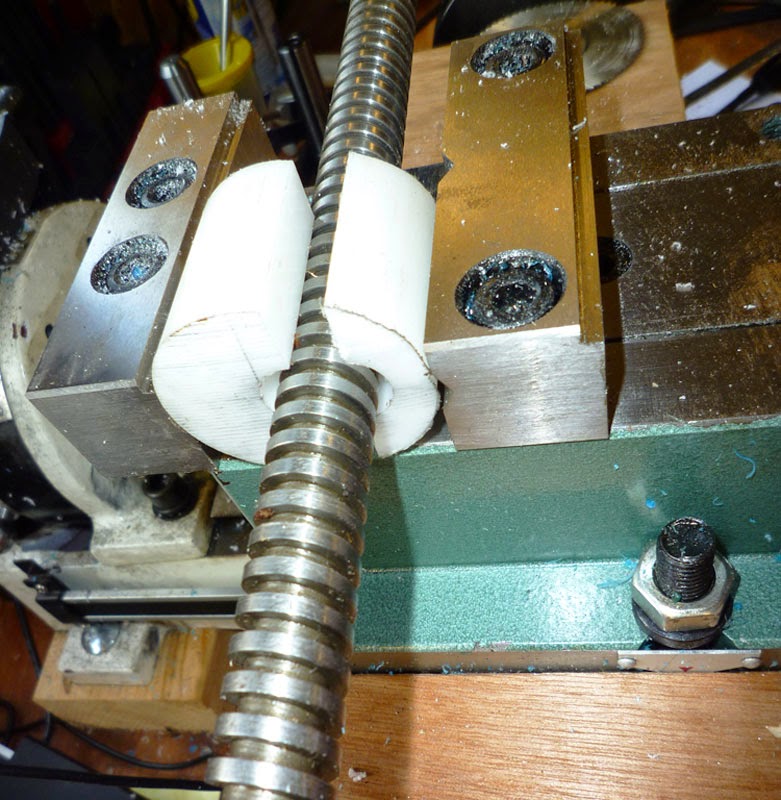

Then set the parts in the vice ready for the the heat gun.

Here is the somewhat amorphous mass of Acetal following heating of the lead screw and compressing the melting Acetal with the vice.

Here it is with the lead screw removed, ready for machining

First side machined with a fly cutter.

I also machined the other 3 sides to give me a rectangular shape so that I could then machine the boss on the top

I removed the vice from the bed of my mini mill and replaced it with a rotary table, using one of the clamping studs through the threaded part to hold the piece steady.

I then machined off the remaining flat area once I was happy with the size and location of the boss.

My camera battery died at this point, so unfortunately I do not have a comparison photo

I then re-assembled my lathe, upon doing so I realised that the thread was not actually parallel to the sides of the new nut but skewed, probably due to a longer part of the lead screw being out of the back of the vice at the time of melting and hence it sagged in that direction.

Fortunately this does not really matter, so long as there is clearance all round the nut, the boss is secured in the hole in the top slide and the thread is aligned with its mounting points at each end of the saddle, it all still works perfectly.

I now have a serviceable top slide once again with no noticeable backlash, and should the nut at some point fail, I have plenty of Acetal to make another, potentially better one.

I would thoroughly recommend this approach to anyone else who needs to replace or create a nut with a difficult to reproduce thread.