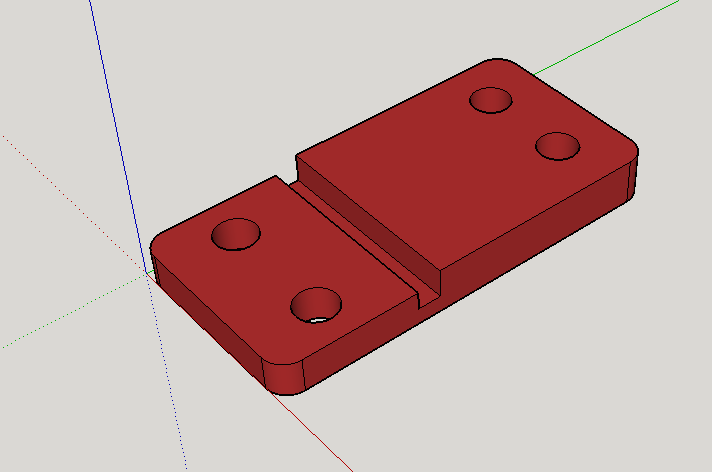

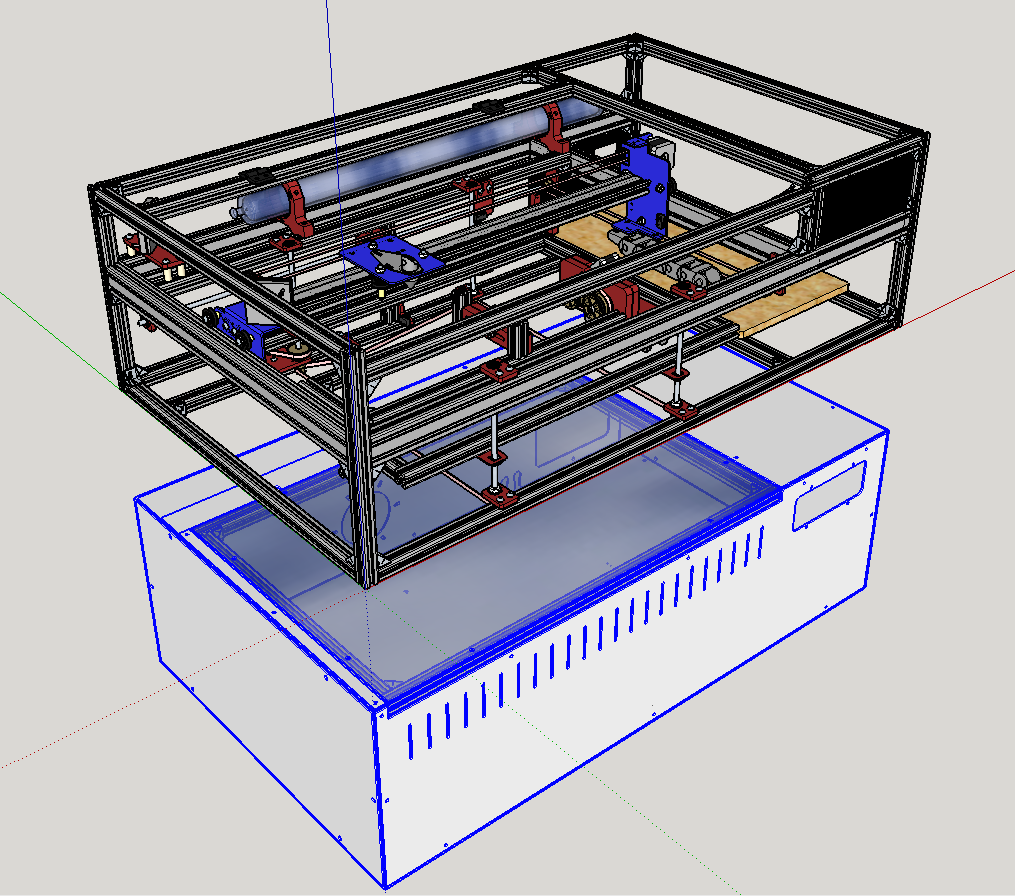

Many of the parts for the Buildlog.net 2.x laser call for 6mm (1/4″) Acrylic/HDPE/whatever, others are 12mm (1/2″) at their thickest and then reducing to 6mm or thinner.

One obvious way to machine these from something like Acrylic or HDPE would be to use a milling machine and assorted drills/mills. Some of the flatter items could also be cut from Acrylic with a laser cutter (HDPE does not cut well with a laser cutter and tends to melt instead).

Now I have both a milling machine and a laser cutter, either or both of which could be brought to task here, however I also have a 3D printer and since I have already modelled all of the parts in Sketchup anyway, I see no reason not to use that for printing the parts.

The cost of the PLA will be far less than the cost of a sheet of suitable Acrylic or HDPE, plus it gives me numerous sample items to use for dialling in the accuracy of the 3D printer itself, which has been having some teething issues.

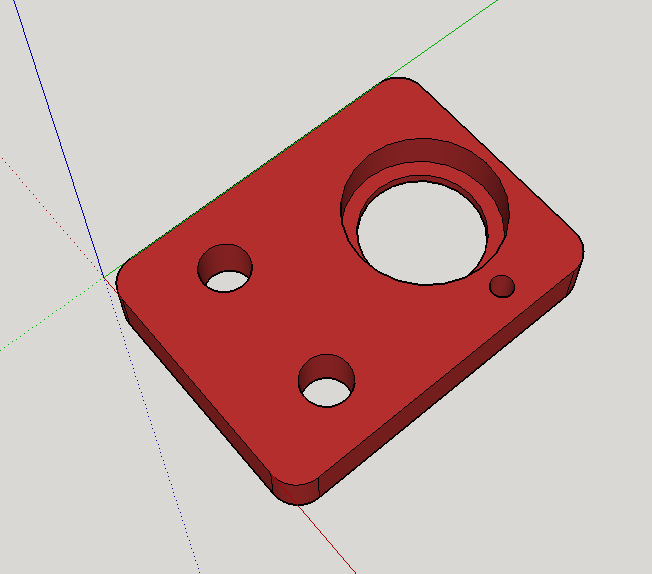

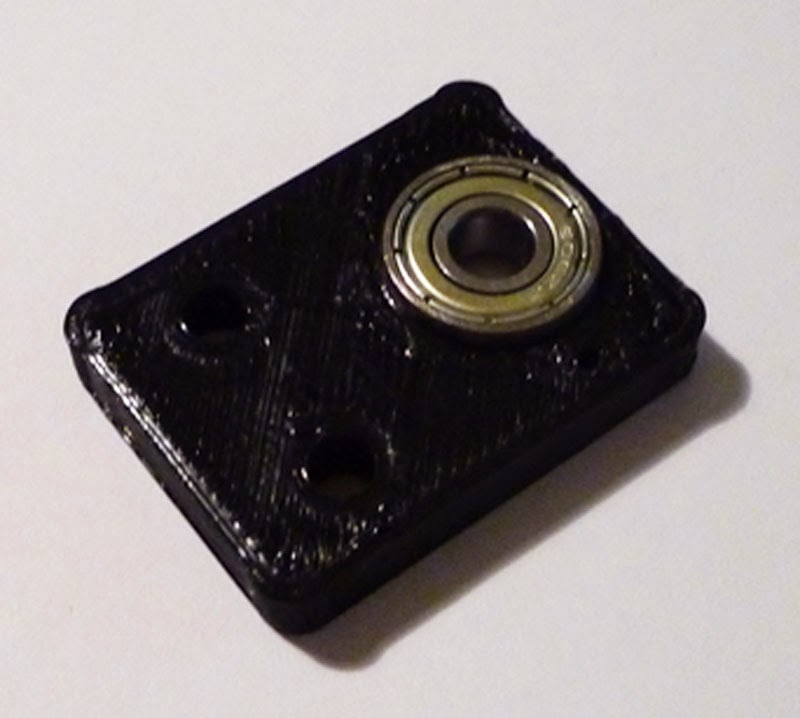

Now there is already a set of STL files for the various parts available from Scott Shwarts in his build log, and another set on Thingiverse, however I have redesigned some of the parts for use with metric bearings, so wanted to have full control over tweaking the parts and therefore I have been generating my own STL files from my Sketchup components, although I may yet use some of Scott’s additional mounting brackets.

For example here is one of the Z axis bearing brackets I have printed with a 606 bearing installed (6mm ID, 17mm OD, 6mm thick).

It took about 10 minutes to print and uses 1939.6mm or 4.7cm3 of filament. Unfortunately the black PLA does not always photograph very well as it is somewhat shiny and tends to reflect the light.

Cost wise, the 1KG roll of 1.75mm filament was £11.99 with free shipping and has about 350m of filament on the roll so the cost of filament in this part is (11.99/350*1.9396) £0.066.

The 606 bearings were £2.89 + £0.20 P&P for a pack of 10 from seariver2009 on ebay, or about £0.31 each.