The Chinese Laser cutter/engraver arrived at about 18:00 last night (Friday), which is pretty impressive since I had only received the dispatch note and tracking number from the ebay seller that morning and it was quoting a delivery date of Monday, possibly Tuesday.

The box was a lot heavier than I expected, however this is because I was unaware that the main case is actually reasonably thick powder coated steel sheet, whereas I had assumed it was fibreglass or some other lighter material.

Having opened the box there was a large bundle of bubble wrap sat on a reasonably thick sheet of expanded polystyrene. It looked like whoever packaged this item used the best part of an entire roll of bubble wrap.

Having removed the bubble wrap, there was then a layer or two of stretch wrap over the top and sides of the unit which again took a while to remove.

My main concern since ordering this item is that the laser tube would have been smashed in transit, however I needn’t have worried as it was still fully intact and well cushioned in its mounts at the rear of the unit.

The laser had obviously been test fired at some point as there was a tiny amount of water still leaking from the cooling pipes and onto my lounge floor.

In short I was very impressed with the level of care taken to ensure that this item reached its buyer in the best possible condition, even considering the less than optimal treatment it will have had from the courier – there were noticeable holes/damage to the outer cardboard box, however none that would have caused too much concern even without the many levels of padding.

One slightly odd thing was that despite the water pump and fan being 220/240V items, they both had US style 2 prong plugs! The kettle style connector for the main unit however has a UK style 3 pronged plug.

There were a couple international adapters included for use with the fan and pump, however one of the metal tips promptly fell off one of the round European style prongs within seconds of me even picking the adapter up. Needless to say, these adapters are of such poor build quality that they will be going straight to the rubbish bin without ever actually being used.

The fan unit has had some pretty bad press from other buyers, and I am not surprised, less than a third of the inlet face actually covers the exhaust port of the engraver, and over half simply sticks up above the entire unit. As such much of the fan’s potential to move air is wasted on moving air from the room, rather than from within the engraver itself.

The aquarium style pump comes with a screw in brass barb connector for use with the silicone coolant tubing, which is additional to what some other buyers have found with their units in the past.

The controller board has obviously been updated from the previous parallel types as this one only has a USB connector – even the included ‘Chinglish’ manual with tiny indecipherable pictures, that have been photocopied so many times you can make absolutely nothing out, still talks about connecting via the parallel port.

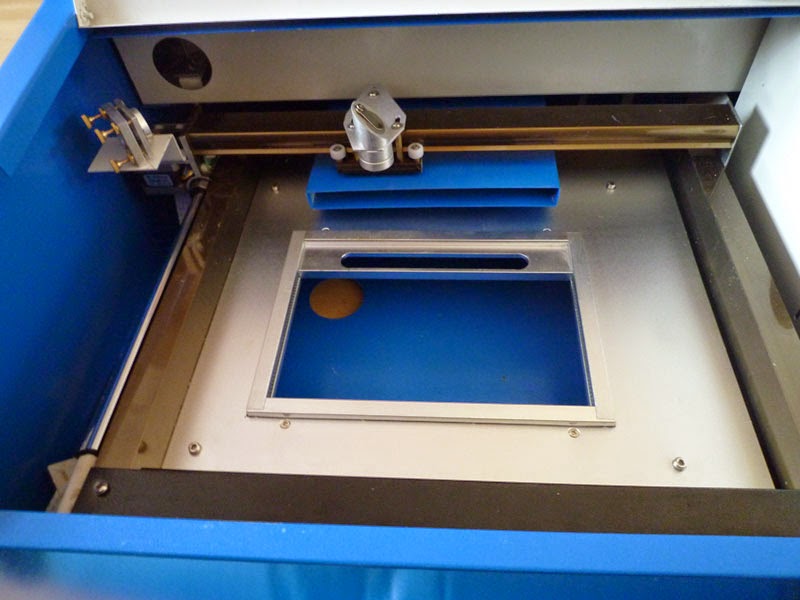

The ribbon cable largely floats free within the bottom of the cutting enclosure as the double sided ‘hold down’ tabs have completely failed to do their job.

There are precious few, if any, safety features on this unit – no cover interlock switches to prevent you from sticking things in the path of the laser beam, no laser warning stickers, nothing to stop the laser in case of coolant failure or overheating, no emergency stop switch, this list could go on and on, all this despite claims in the listing of being CE, FDA and ISO 9001 compliant, it does however have optical switches for determining the home position, but you get the picture.

This is a unit built to a price, and that price is actually a fair bit less than what you can buy the various parts for individually. and if you buy one of these units, you have a pretty good idea of what you are buying, and the corners that have been cut.

In my case, this is intended as a parts donor for a Buildlog.net 2.x laser, although it will be a shame to waste the steel case, so I may look to use the panels for parts of some other future project.