- Position 1 both the 24V and Laser power supplies are off

- Position 2 only the 24V PSU is live

- Position 3 both the 24V and Laser power supplies are live.

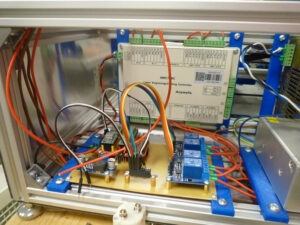

The DSP is wired directly to the 24V PSU, the stepper shield is wired via the E-Stop switch, but again has a dedicated connection to the 24V PSU.

Rather than run multiple wires from the 24V PSU for the various relays, these each make use of a dedicated 24V output from the DSP, this also makes for shorter wiring.

The power connections to the connector block and the 24V PSU are using 3.5mm ring connectors that are crimped onto the cables.

For the screw terminals I am using bootlace ferrule crimp connections

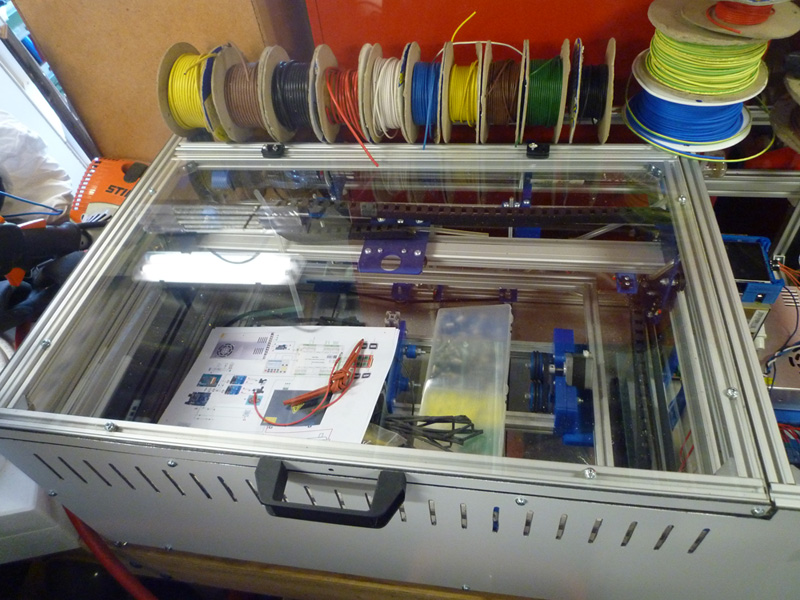

The shot below shows the wiring on the terminal block,

some of which goes out the back of the frame, this is for the extractor fan connector, pump connector and IEC inlet filter power connector.

At the time this photo was taken, I had not yet made the cutouts in the rear panel, so it had yet to be attached.