For some unknown reason I cut two sets of frame pieces for the bench top – obviously I was having a funny five minutes when I was working out my cutting list.

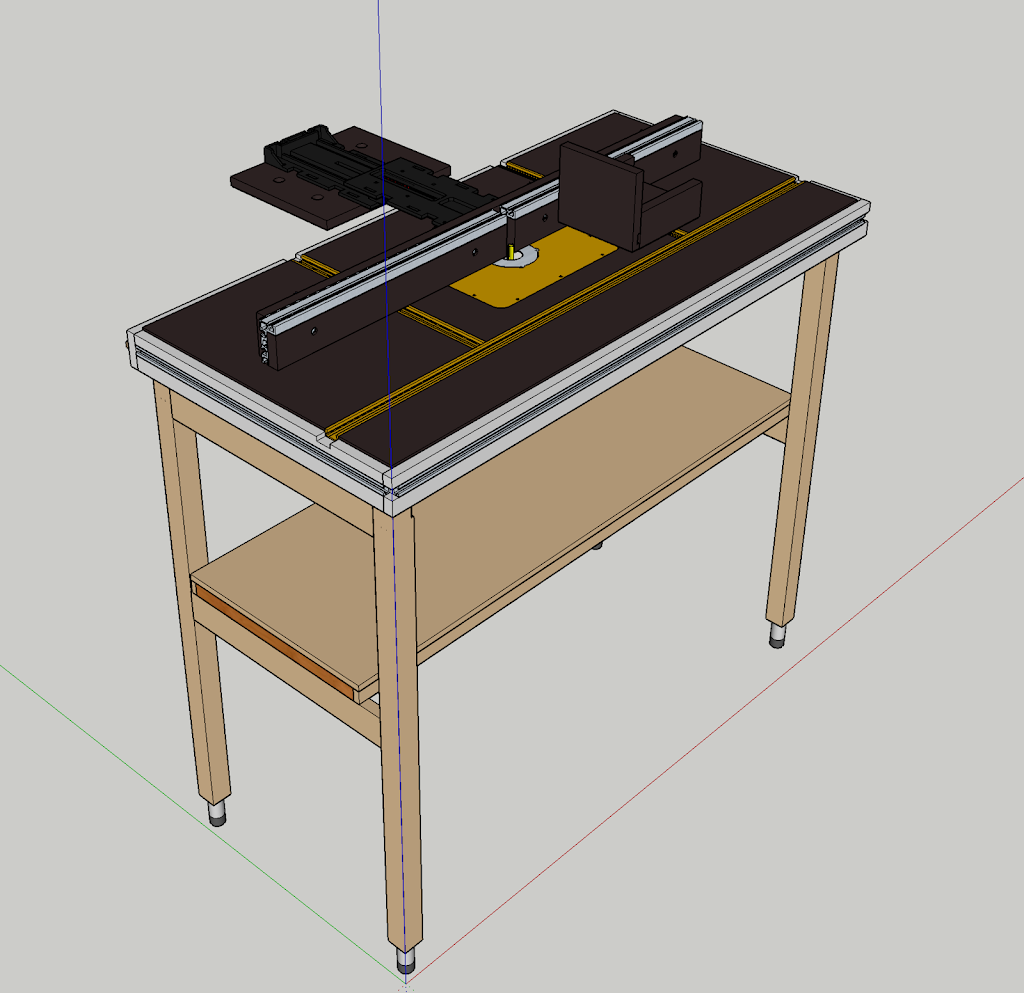

I was wanting to build a router table anyway, so why not use the spare frame for that.

I needed a router table to rout the dados in the sides of the bench top for the T-Track and also the dados in the edges of all of the extension table parts, so now was a good a time as any to make one.

This version may just be temporary and may yet be replaced with a piece of 18mm phenolic plywood, as shown in the Sketchup drawing, I will see how it goes.

The router table surface is made from an off-cut of kitchen counter that was left over from making a window cill for my Cinema room, it just needed trimming to size and then a hole cutting in the middle for a router plate.

I bought a Bosch 1617EVSPK kit a while back on a trip to the USA along with an additional base for use in a router table and a router plate.

Unfortunately it was stolen when my garage was broken into, so last year on another trip to the USA, I purchased another one along with some of the accessories that went missing with the router (they were in the case).

The sharp eyed, may notice that this is not an Incra MagnaLOCK router plate, but a Bosch plastic plate. I thought I would practice on this first, just in case I messed up in any way.

Good thing I did, as I initially drilled all of the mounting holes for the router in the wrong place – I used the holes for the cap head screws instead of the countersunk screws, not necessarily an issue as they all line up the same, except that the router plate has an additional hole for adjusting the router height from above the table and this is no longer in the correct place, so I re-drilled the mounting holes and all is good.

The hole was initially cut using the track saw and then I used the track, a 30mm collar and a worktop bit to cut the opening to size. the rebate was cut using a laminate trimmer again riding against the track.

The Bosch plate is smaller than the Incra one, so I can still increase the size of the cutout for that one at some point.

I used the track again as a fence for routing the dados in the sides of the table top frame.

Trial fit of the t track in the frame.

Next I cut all of the dados in the pieces that make up the two extension tables.