Here are the rest of the parts printed in black PLA, all of the items that require 606 bearings have them installed and secured with M3x10 screws.

Cost of the printed parts:

|

|

Filament |

Cost |

|

Total |

| Part # |

Description |

(mm) |

(cm3) |

(£) |

Qty |

(£) |

| B17005 |

Z Lift Plate |

1939.6 |

4.7 |

0.066 |

7 |

0.465 |

| B17007 |

Limit Switch Bracket |

2023.9 |

4.9 |

0.069 |

1 |

0.069 |

| B17008 |

Y Motor Plate |

5481.4 |

13.2 |

0.188 |

1 |

0.188 |

| B17011 |

Cover Stop |

6755.2 |

16.2 |

0.231 |

1 |

0.231 |

| B17013 |

Rear Mirror Bracket |

6860.0 |

16.5 |

0.235 |

1 |

0.235 |

| B17015 |

Cover Interlock Switch Plate |

1157.8 |

2.8 |

0.040 |

1 |

0.040 |

| B17017 |

Z Motor Bracket |

11182.5 |

26.9 |

0.383 |

1 |

0.383 |

| B17035 |

Z Adjustable Idler Bracket |

2950.4 |

7.1 |

0.101 |

1 |

0.101 |

| B17040 |

Z +ve Switch Bracket |

3177.1 |

7.6 |

0.109 |

1 |

0.109 |

| B17041 |

Gantry Idler Bracket |

3524.0 |

8.5 |

0.121 |

1 |

0.121 |

| B17042 |

Y Shaft Bearing Bracket |

2481.0 |

6.0 |

0.085 |

2 |

0.170 |

| B17043 |

Y Idler Bracket |

2703.5 |

6.5 |

0.093 |

2 |

0.185 |

| B17044 |

Z -ve Switch Bracket |

1773.7 |

4.3 |

0.061 |

1 |

0.061 |

|

Total |

|

|

|

|

2.358 |

So the total cost of PLA for these printed parts is £2.358 (about $3.68) compared to a cost of $75.00 (about £48.00) + P&P to buy a set of machined HDPE parts from one of the members of the Buildlog.net forum.

For anyone interested, my Sketchup and STL files are all available on GitHub.

I have yet to include the cost of the laser tube mounts, and these costs do not include the electricity required to run the 3D printer, but this is still going to work out at less than 10% of cost of the HDPE parts – his raw material cost was quoted as $25.00 (about £16.00) before factoring in 4 hours of machining time, for which he only charges around $12.50 (£8.00) an hour, which to be fair is a pretty cheap rate.

OK, so this is not an entirely fair comparison, I am not charging for my time, mainly because I can set the print off and leave it to complete whilst I do something else, something you can’t really do with a milling machine, and my raw material is much cheaper and has minimal waste compared to cutting the parts from a sheet of HDPE.

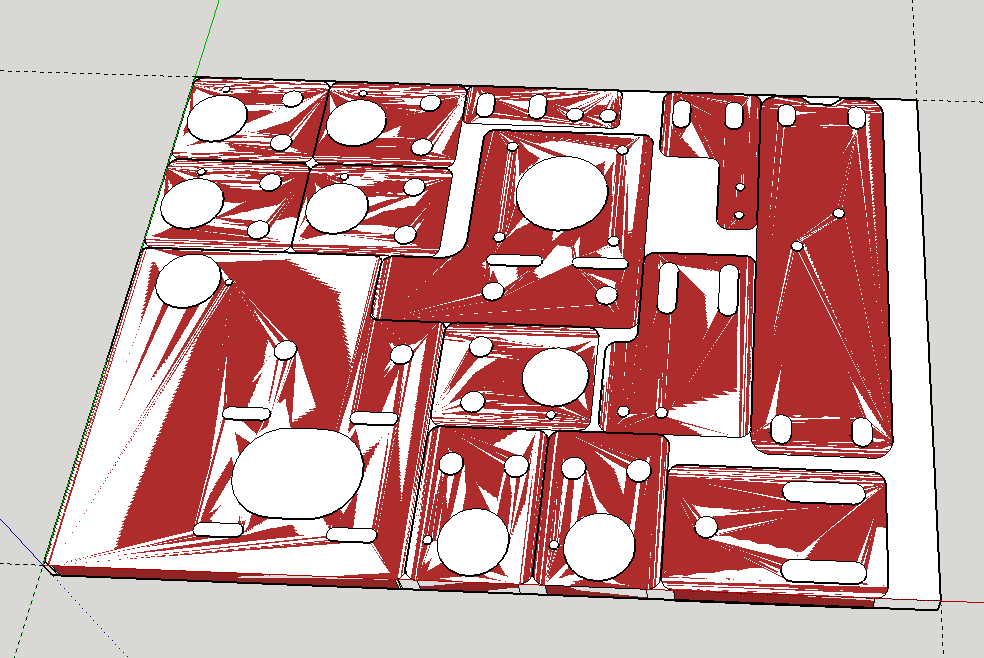

I did come up with a pretty good cutting plan for laser cutting the 6mm pieces from an A4 (150x210mm/5.9×8.26″) sheet of acrylic:

The 12mm cutting plan included the parts for the rotational axis and is for a 300x300mm (11.8×11.8″) sheet of acrylic.

Some of the parts would still require additional machining – boring bearing pockets, machining different heights onto the part, etc.

The Raw material prices again would be way more than that of the PLA filament to print them from scratch, the 6mm A4 sheet alone would be about £3.70 ($5.80) – same price for a similar sized sheet of HDPE. I am not saying the savings are huge, but in this case time required and cost outweigh the potentially better looking acrylic solution, there will be times in the future where this will not be the case.

An A4 12mm sheet of acrylic will be about £12.00 ($18.75), so even with the large areas to be filled for the rotational axis parts, I can always use a relatively sparse fill, I have been using 0.4 so far, I could knock this down even further for these thicker parts most of which will not see much if any stress in any direction throughout their lives, it will almost certainly still be cheaper to print them with PLA.

For each item or set of items, one needs to think about the material requirements and ease of machining to reach the end goal, as I have already mentioned I had the option of creating these parts by cutting them out on my Chinese laser cutter, machining them on my mini mill or printing them on my 3D printer, in this case, in my opinion, the 3D printer was the best choice.

I did a cost comparison once

before between purchasing 20x20mm aluminium extrusion and printing an equivalent in PLA or ABS.

At the time of writing it was still much cheaper to purchase the aluminium extrusion than to bother printing it. PLA filament prices have come down a fair amount, nearly halved in price if you buy from lesser known suppliers, and now there is not a huge difference in cost between the two options.

That being said, I would still purchase the aluminium extrusion as it will be produced to a much higher specification and be far stronger than my printed part can hope to be, so again, just because you can make something, does not make it the best or right solution.

There will also be times where cost does not enter into the equation and the sheer satisfaction from making the item yourself will completely outweigh all other factors.