I have stated from the beginning, that I was not overly happy with the tilting column design of the Sieg X2 Mini Mill and would have preferred the solid column as sold with one of the models from LittleMachineShop.

As such, ever since it became available at ArcEuroTrade, I have been interested in the Fixed Column Conversion Kit.

The base adds an additional 30mm of Y travel, and as such comes with a longer lead screw.

I missed out on one of these the first couple of times they were in stock, so this time I ordered one as soon as I received the email to let me know they were in stock once again.

The price was £117.89 ($182.75) with free next day delivery by courier.

The parts were well packed, each of the cast iron items were packaged separately in their own cardboard boxes, with plenty of polystyrene filling out the remaining space in the main box.

The column had some additional polystyrene inside its box to level out the rear of the column.

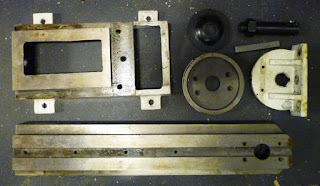

Here are all the items that you receive still in their protective sleeves.

The first task, after cleaning the new parts, was to drill and tap the holes for the air spring and also the linear scales.

This time I mainly performed the task on my pillar drill, as I was not attempting the job with the mill assembled and could measure the locations from the current pieces.

Next task was to dismantle the mill so that the new items could be swapped in.

I simply removed the table and headstock assemblies and set them aside.

Removing the electronics box involved unscrewing every item from within the enclosure in order to reach the mounting and earthing screws.

After drilling a couple of new holes in the bench for the extended base, it was time to start putting it all back together again.

I checked the squareness of the column to the base with a large steel set square before tightening the bolts securing the column.

All back together again and it all still works (always a bonus).

I still need to do some lapping on the new dovetails to even out any tight spots, but so far I am happy with the upgrade.

As seems to be the case whenever I take the mill apart, fewer items are put back.

These are the items that I have left over this time:

Sure, I could have achieved much of what this kit offers, by way of rigidity, by bolting a plate of aluminium or steel to the back of the base and column, but I personally believe that this is how the mill should be supplied.

However, I now have all of the additional parts I would need should I decide to make an X2 freak like Hoss.

I am undecided on the additional Y travel of the freak, but I may well machine the old column and use that to give me more X travel.