I spent a very enjoyable day at the Model Engineering Exhibition at Alexandra Palace on Saturday with my son.

There were large stands for several of the big name vendors RDG Tools, Axminster, Warco, Chester Machine Tools, as well as many club stands for model trains, both electric and steam static displays for model boats, traction engines and engines – the most notable of which was for Robot Wars.

I went prepared for multiple trips back to the car with heavy purchases from various vendors having purchased way too much at special show prices. The reality however was somewhat different.

I had done my homework before attending and had made a list of many potential purchases and the best prices I had found on-line for them as well as making a note of weather or not shipping was included.

For many of the items it was still way cheaper to buy them on-line from a vendor that was not attending the show, such as Chronos, or Amadeal, or simply wait until my next visit to the USA and buy from the likes of AMTools.

I was particularly disappointed with the prices on the RDG Tools stand as their prices were almost exactly the same as from their on-line shop or ebay store, where free shipping is included in the price, and most items were being undercut price wise by Warco at the show itself.

In the end I bought a few carbide reamers, a carbide countersink/deburring bit, a couple of carbide roughing bits and an R8 face mill holder from JB Cuttingtools, the last item being just £8.00 compared with around £26 for the cheapest one I could find on ebay, plus they threw in a bunch of other carbide mills/reamers for free.

and a clamping set for the rotary table (£12.00, normal price £15.00) – the rotary table on its own at the RDG Tools stand was £150.00, the dividing set an additional £50.00 and the tailstock £45.00.

I also bought from them a 3″ milling vice for £40.00 (normal price £55.00).

A 3 piece fly-cutter set for £14.00 (currently on sale at £15.32), a Keats angle plate for £22.00 (normal price £24.00)

and an R8 ER32 collet chuck for £40.00 (normal price £40.85 so not that much of a bargain).

I was thinking about buying the ER32 chuck from an ebay vendor in Hong Kong for about £5.00 less after shipping, but thought I would rather buy a Chinese knock-off that is at least backed by a UK vendor.

All these items were substantially cheaper than anywhere else at the show. I am not saying everything on their stand was the cheapest, some were indeed cheaper at RDG Tools, however these items I could buy much cheaper than either of them from Chronos with free shipping The items I did purchase, however, I would struggle to find at cheaper prices elsewhere, especially the rotary table.

Having made it home with this little lot, I decided to check out all of my purchases to make sure I did not have any “lemons”!

All looked ok and appeared to be fit for purpose, my only gripe being with the handle for the rotary table.

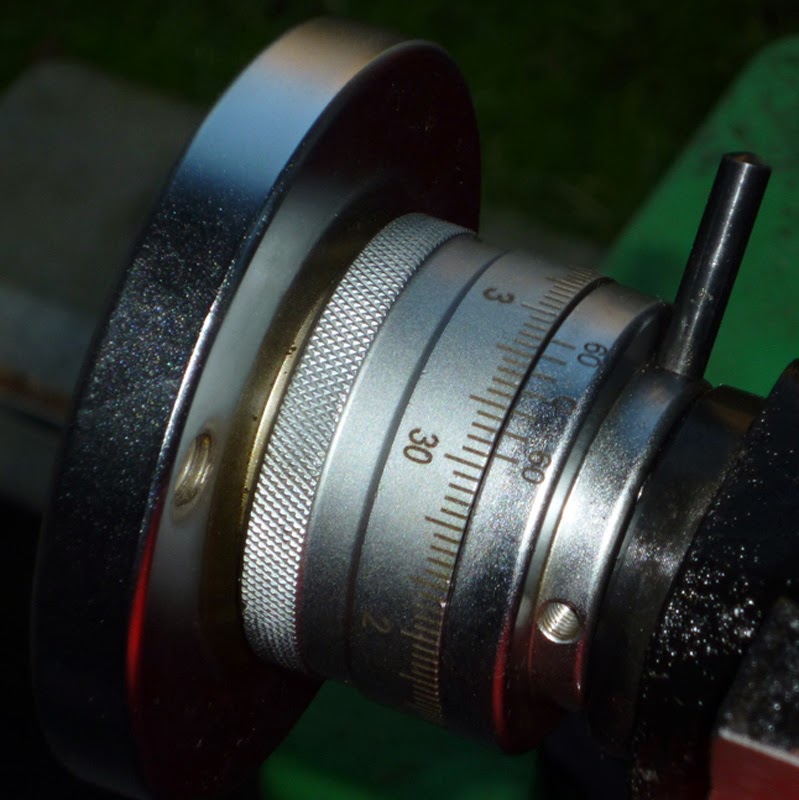

When I turned the handle, I noticed that the scale was not flush up against the vernier and in fact seemed to wander in and out as the handle is turned.

Initially I thought that the spindle was bent, however removing the handle and attaching the dividing head parts proved to me that this is not the case.

The issue is also not with the scale, as this will happily sit flush on a flat surface, and even flat up against the vernier (without the handle).

The issue is with the handle itself and also with the key that engages it. Firstly I do not believe that the engaging hole in the handle is central/square to the outside – probably machined with the handle mounted at an angle in the chuck.

Second the key is a mess that looks like it has had a rough time when the handle was “hammered” on.