I placed my order for 3 x 1M lengths of Makerslide from Amber Spyglass on 19th March, after waiting for it to come back into stock from before Christmas.

I check my order on 23rd March only to find it is still pending, and now there is a message in the shop stating that they are closed for orders and nothing will ship until 13th April.

I appreciate that this is a part time job for Catalin, the owner, and also that he has back orders of eShapeoko kits to fill, but waiting nearly a month to ship something that is in stock at the time of ordering is a bit much.

He has a bit of a captive market here in the UK, the only other options are Inventables in the USA with the associated shipping and duty costs or myhobby-CNC in Germany.

On the plus side for me in this instance, myhobby-CNC offer a cutting service and will send you pre-cut lengths with an estimated delivery time of 2-4 days.

Maybe I was a bit over zealous and hasty in my actions, but I cancelled my order with Amber Spyglass and placed a new order with myhobby-CNC for the exact lengths I require, thereby additionally saving me from having to cut it myself and ending up with various odd length off-cuts that I have no use for at this time.

This actually ended up saving me some money, since 3 x 1m lengths of Makerslide from Amber Spyglass at £12.00 each plus shipping at about £7.50 after VAT comes to £43.50 ($67.50).

My order from myhobby-CNC was 1 x 700mm length of Makerslide at 11.77 Euros, 2 x 560mm lengths of Makerslide at 11.20 Euros each, plus 12.56 Euros shipping comes to 43.15 Euros or £32.58 ($50.50), thereby saving me almost £11.00 ($17.00) nearly the cost of a 1m length.

Don’t get me wrong, myhobby-CNC are not cheaper than Amber Spyglass, but for this specific case, because of having to pay for extra material I did not need, and not having to cut the Makerslide myself, the decision made sense and saved me some money into the bargain.

To be fair to Catalin, he emailed me and then rang me to confirm I really wanted to cancel my order and informed me that whilst any new orders would indeed be delayed until 13th April, he was still working through his backlog and was actually about to ship my order out.

He was very understanding and understood my reasons for cancelling with regards the message being presented by his website and also my specific length requirements, where I was always going to have some waste, no matter which lengths I went for – maybe I will have better luck with him next time.

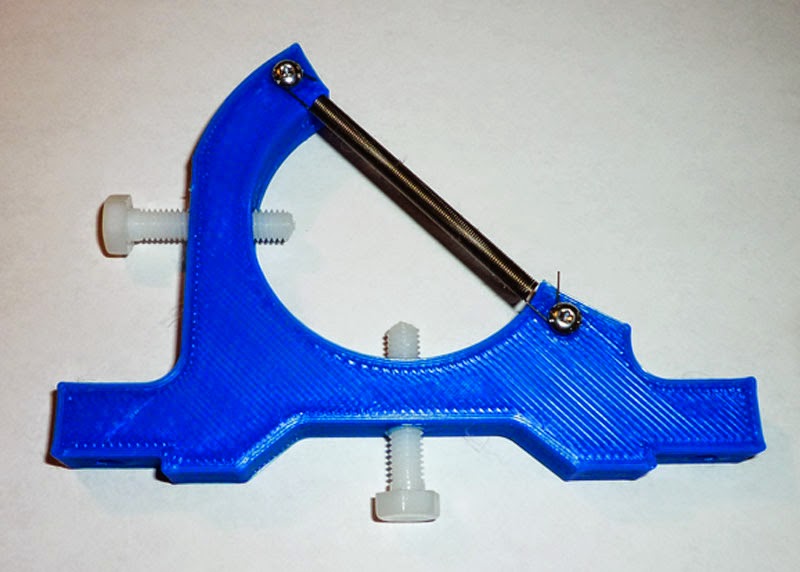

I finally decided to print some Laser tube mounts, however, rather than sticking with the 120 degree screw angle I opted for 90 degree as this would make adjustments simpler.

I used 9145.3mm of filament for each one for a cost of £0.68 for 2, the M6 plastic hex head screws from Orbital Fasteners were £0.05 each, 4 required, so £0.20 total, the springs came from some old printer I dismantled and were free, it remains to be seen if I need some stiffer springs from my spring collection, I may also decide to use a lock nut with the plastic screws

I printed made my own idler pulleys

each of which used 343.6mm of filament, 4 of these cost £0.05, again I bored these to size on my Mini Mill, as they were quite ‘bumpy’ on the inside and then press fitted the 625 bearings £1.61 for 10 from ebay seller warm-tech – I bought 40 so I would have some spares after the idlers and V wheels.

Here is one of the gantry plates with the V groove wheels installed using the same 625 bearings.

For both the V groove wheels and the idlers I decided to skip the cost of the ‘precision shims’ at $0.20 each from OpenBuilds, or £0.30 each from Amber Spyglass, and used a standard M5 washer instead at £0.41 for 100 from Orbital Fasteners.

Based on the knowledge that there will be a tiny amount of difference between each of the V wheels, for the fit of the bearings both from a bore and depth of bore viewpoint, (this is even stated on the websites you can buy them from) my view was that a standard washer was precision enough and cheaper by a factor of about a hundred.

One can occasionally become a little too hung up on accuracy in places where it is not necessarily that important – measure with a micrometer, mark with chalk, cut with an axe – an extreme scenario, I agree, but how often have you found yourself measuring something to several fractions of a mm or thousandths of an inch, only to mark the line with a thick pencil and then cut with a chop saw or hand saw that is accurate to a couple of mm or 1/8″ at best?

Was the pencil mark centred on the dimension, or to the left/right, how accurately did you line up the saw, again did you cut the line in the middle, to the left or to the right. Sure you can take care to ensure you mark to the right (oversize) of the dimension and then cut on or to the right of the line allowing for the kerf of the blade and with care you can end up with a pretty accurate length of raw material.

All of these inaccuracies add up and some can be negated by tightening the fasteners holding the items together, but my view is to take your wins where you can and where it will have the most impact

Worrying over a few 0.01 of a mm or ten thousandths of an inch for a washer, where the overall dimension is not critical is a waste of time and money – you only really care about the thickness of the spacer, the inner bearing and how accurately the V wheel can be lined up compared to the others on the same end of the axis, the second bearing is there only to provide concentricity for the V wheel, how far that is spaced from the first one is to all intents and purposes irrelevant.

I used the eccentric spacers at £1.35 ($2.00) each (3 purchased), aluminium 1/4 spacers at £0.13 ($0.20) each (6 purchased) and Delrin V groove wheels at £1.01 ($1.50) each (9 purchased) all from OpenBuilds. Using nylon spacers in my opinion could lead to the spacers being crushed by tightening the V wheels against the plate and as a result cause the plate to sit at an angle relative to the cross member, the cost for both the nylon and aluminium spacers was the same, but the upgrade in stiffness made it a ‘no brainer’.

My Drag chain arrived from China, I had ordered 2m of 10x10mm from ebay seller lintashop for £4.09 each plus £2.08 P&P, and 1m of 10x15mm from ebay seller quanshop2014 for £4.25 with free P&P.

Unfortunately when it arrived, all 3 sets were 10x10mm and so I raised a case for the 10x15mm chain and received a refund.

I have yet to see if I can use this for the X axis or if I will actually need the wider 10x15mm chain.

I printed my own version of the High voltage PSU mount, as I wanted it with the cables exiting to the front and rear, rather than top and bottom.

Each one used 7490.3mm of filament for a combined cost of £0.56.

I also found a cheap 24V bilge blower ,with a 4″ (100mm) intake and 3″ (75mm) outlet, on ebay for £10.00 and £8.00 P&P, these normally range in price from about £45.00 to £150.00 new.