I came across this video on YouTube of a CNC machine using 2 belts as a sort belt on belt rack, I then went searching for other implementations of this idea and came across an interesting thread on the CNC Zone forums where several other people are discussing the same idea.

I thought I would also give this idea some exploration as a possible cheaper alternative to R&P and see what I could come up with.

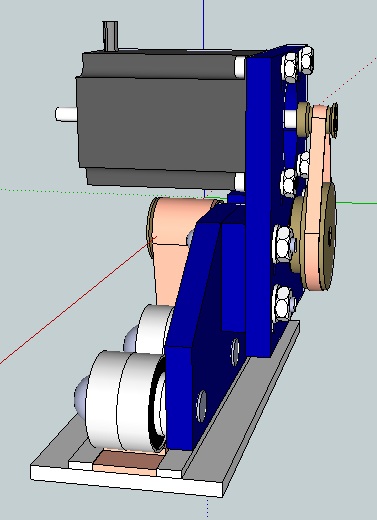

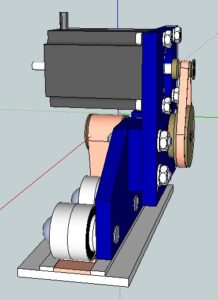

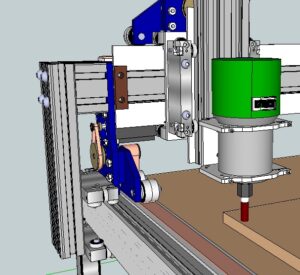

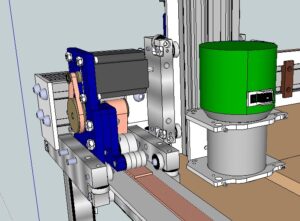

There were a couple of redesigns along the way before I settled on the following design

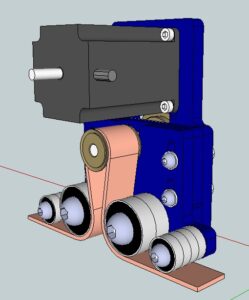

The design makes use of 1 4:1 reduction gearbox and is adjustable vertically for tension in both drive areas – stepper to gearbox and gearbox to drive belt, makes use of flanged Oilite bearings and spacers for the driveshaft between the two halves of the gearbox, these are very simple design and very low maintenance and will continue working regardless of how much dust gets on them.

I like bolt through designs as one can apply more tightening force to steel on steel with no worry of thread stripping than you can with steel on aluminium, sure, not all elements of the gearbox are 100% bolt through, though I can continue to aim for that goal.

I may also look to enlarge the axle for the gearbox for greater rigidity.

Deciding between 2 continuous belts or one long belt and a ‘tank track’ style loop is another area to think about.

2 long belts is more costly, but has the added advantage of providing a cover for the “rack”, although keeping that cover aligned is a disadvantage.

Preventing the loop from catching on things is a disadvantage, as is increased wear on that loop, however alignment will be much simpler.

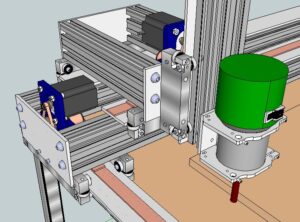

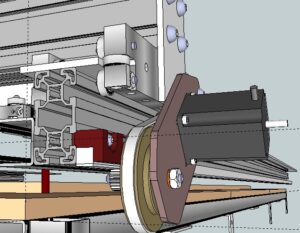

Integrating it with the rest of the design proved just as interesting:

I like the idea very much as it is potentially much cheaper than a traditional R&P system and has the potential for some very fast rapids 1000ipm+.

I am still having a few issues with integrating it on the X axis with vertical plates of guide steel.

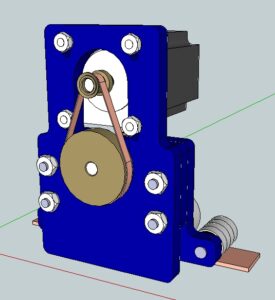

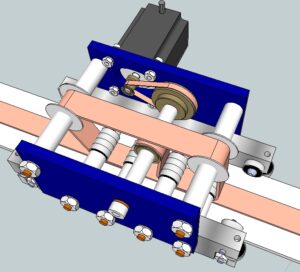

Here’s another version that makes use of the “tank track” idea and can potentially be mounted sideways. less adjustabile due to the location of the bearings, but easily changed to wider belts if required, simply by changing the widths of the drive gear and spacers along with the number of skate bearings.

The top idlers could easily be moved in and also have skate bearings if the friction against the spacer was considered too great, it even uses a standard size belt at 575mm.

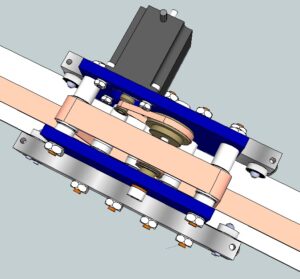

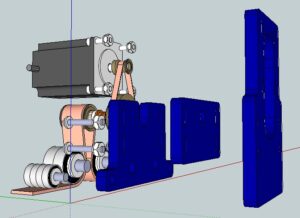

Inboard version of the same thing:

Cost comparisons with the Rack and pinion version are not really favouring the belt drive system.