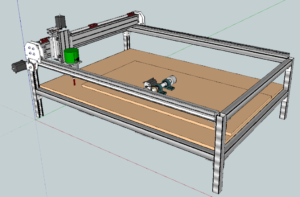

I saw a CNC plasma cutter on cnczone and liked the look of how some of the parts had been made and the ideas behind how they mounted.

I then discovered that the machine in question was a ShopDroids machine.

The extrusions they show are IVTAAG and IVTAAN from Pacific Bearings. The ShopDroids design is intended for a plasma cutter that will have little if any stress placed on the gantry.

The IVTAAG is basically a 50x50mm extrusion with integral V rails.

Looking at the extrusion calculator on the ShopDroids website, these custom extrusions appear to be quite competitively priced, especially compared to mounting V rail to flat steel bar stock.

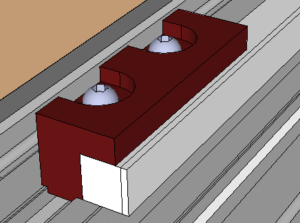

I want something a bit beefier than the IVTAAG, looking to mount the IVTAAQ extrusion, which is 105mm wide but only 18mm thick, again with integral V rails, to an 80x80mm profile to increase rigidity and using the IVTAAS extrusion to for the rails and mounting of the rack for my Y axis.

I am currently awaiting prices for these extrusions from a couple of UK based distributors of the Pacific Bearings products.

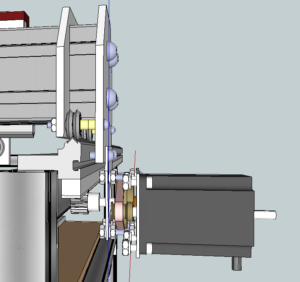

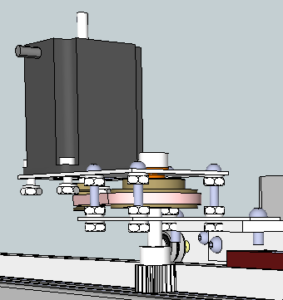

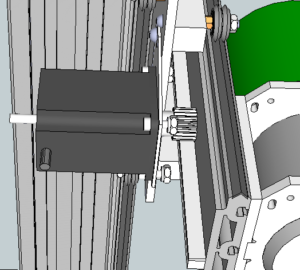

I also like the look of the various ShopDroids gearbox designs, which are not a million miles from some of my earlier ideas:

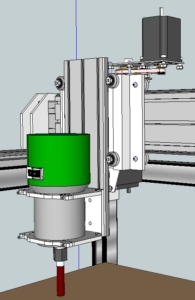

Here is one attached to a Y axis end intended to have an IVTAAG extrusion bolted through it:

This will need a spring of some sort to prevent the Z axis falling in the event of a power cut.

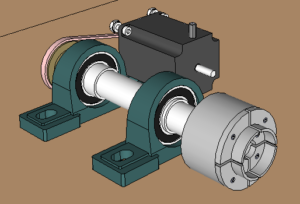

I am also in the process of designing a 4th axis, A or B, depending on which direction it is mounted: